ASTA in Motion - Safe and Sustainable

Electric drive systems—from high-performance locomotives to passenger electric vehicles—require copper components that enable compact designs, high thermal resilience, and maximum energy efficiency.

ASTA delivers precision-engineered solutions that significantly enhance the performance, reliability, and efficiency of electric drive systems.

Traction Transformers

Efficiency & Reliability for Rail Transportation

Traction transformers are the heart of electric locomotives. They must safely convert very high currents, withstand intense vibration, and deliver maximum efficiency within extremely limited installation space. For these demanding requirements, ASTA develops specialized copper conductors and CTC variants that enable optimal winding behavior, exceptional temperature resistance, and compact dimensions—ideal for modern, energy-efficient rail traction systems. With decades of experience and a fully integrated manufacturing approach, ASTA is among the leading suppliers of copper solutions for traction transformers.

As a One-Stop-Shop, ASTA offers a fully integrated value chain—from copper forming and enameling to insulation, transposition, and finished windings—resulting in solutions with exceptional technological depth: custom-designed profiles for tight installation spaces, high mechanical robustness, specialized miniaturization concepts, and precisely defined conductor geometries for fully automated winding processes.

Copper Hairpins

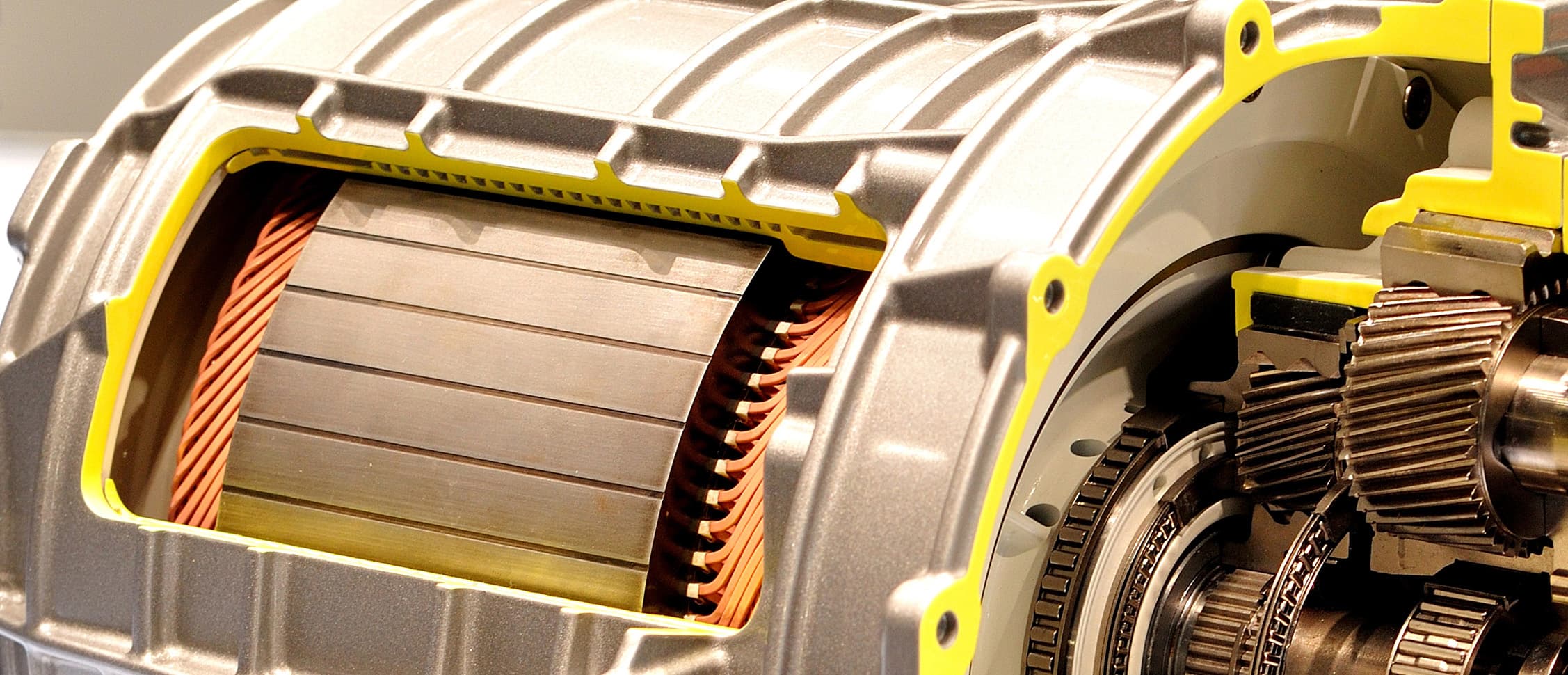

Efficiency & Power Density for Modern Electric Motors

Electric passenger vehicle drive systems place the highest demands on material quality, precision, and thermal resistance. Copper hairpins are a key enabling element of modern stator windings. They allow for compact designs, reduce copper losses, and improve thermal performance—factors that are critical for the range, power density, and efficiency of today’s electric vehicles.

ASTA is among the technological leaders in the manufacturing of conductors for hairpin applications, delivering solutions that are precisely tailored to the requirements of the automotive industry.

As a One-Stop-Shop, ASTA offers a fully integrated hairpin value chain—from alloy and geometry development to cold forming, surface treatment, and insulation—delivering solutions with exceptional technological depth: fully customizable geometries, the highest thermal classes, outstanding energy efficiency, and close partnerships with leading automotive manufacturers and research institutions.